BASE OIL – ALL GREADS

The refining process of mineral oils has improved greatly in the 20th century. The American Petroleum Institute (API) divided all base oils into five separate groups in the early 1990s. The first 3 groups were dedicated to mineral oils and the 2 remaining groups contained synthetic oils predominantly.

The refining process of mineral oils has improved greatly in the 20th century. The American Petroleum Institute (API) divided all base oils into five separate groups in the early 1990s. The first 3 groups were dedicated to mineral oils and the 2 remaining groups contained synthetic oils predominantly.

Group 1, 2 and 3 are all mineral oils, with chronologically increasing refining process severity. Base oils under Group 1 are made using solvent-refining or solvent-extraction technology.

Base oils under Group 2 are produced by hydrotreating or hydrogenation. It is a process that uses hydrogen gas to refine oils, but they are better for converting components like aromatics that are undesirable, into hydrocarbon structures that are desirable.

Base oils in Group 3 are produced in a similar fashion as Group 2, the only difference is that the process of hydrogenation or hydrotreating in group 3 is coupled with high pressures and high temperatures. This leads to convert all the undesirable components in the oil into desirable hydrocarbon structures.

When you compare these groups of mineral oil bases, you will see that highly refined oils provide greater benefits in terms of thermal stability, oxidation stability, pour point, operating temperature, and viscosity index. But the oil starts to show some key weaknesses, affecting additive solubility and oils biodegradability.

Group 4 contains only one type of synthetic oil called polyalphaolefin (PAO), these synthetically created hydrocarbons are the most widely used base oils form the synthetic category. They are created using the polymerization process that gives an olefinic tail by the introduction of ethylene gas. This process makes the chemical structure of PAOs quite similar to that of highly refined mineral oils form Group 3. While PAOs lack in lubricity, additive solubility, film strength and seal shrinkage, they have powerful advantages such as superior oxidation stability, higher viscosity index, lower volatility and excellent performance in high and low temperatures. POWs are employed widely for lubrication; they are especially preferred when the equipment is expected to reach higher temperatures.

Group 5 contains all the remaining oil bases which are mostly synthetics. Most common oils that belong to this group are polyolesters, diesters, polyalkylene glycols, silicones and, phosphate esters.

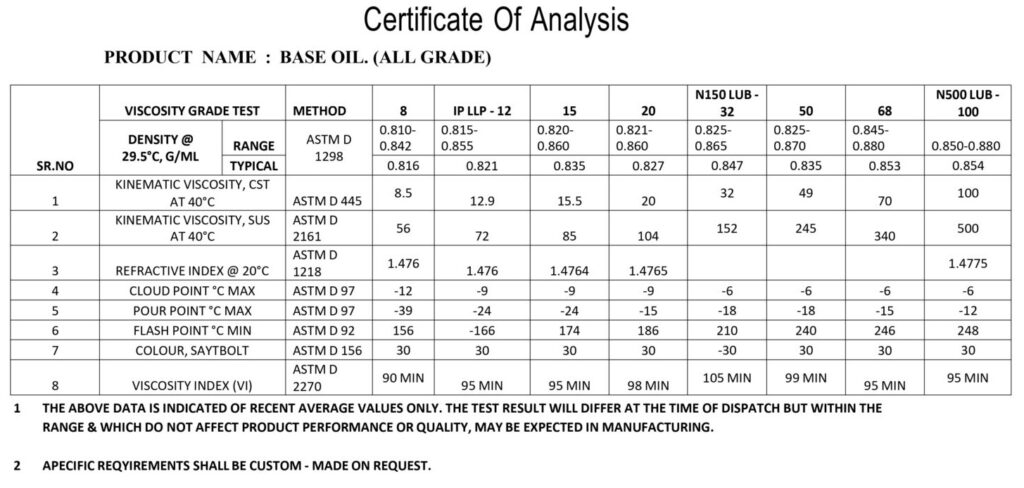

BASE OIL TEST REPORT (ALL GRADE)